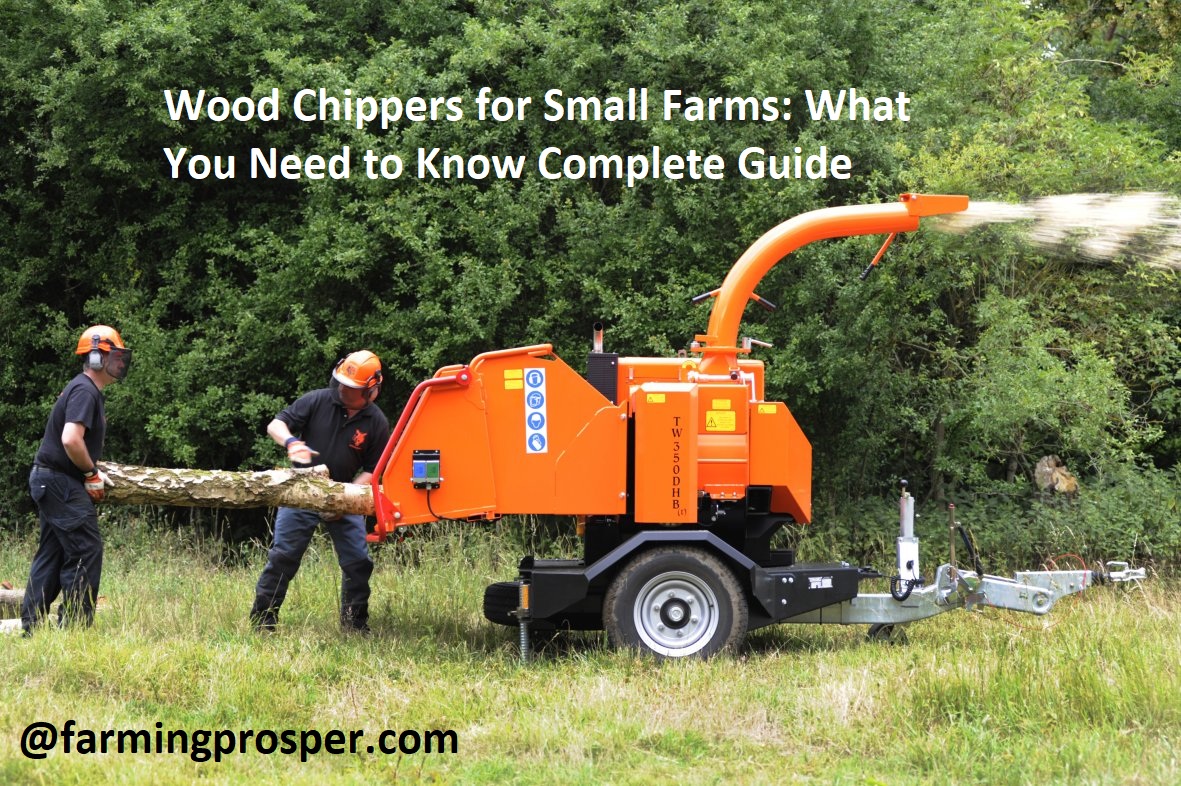

Are you a small-scale farmer wondering what the best wood chipper for your farm is? You’ve come to the right place. In this blog, you’ll get all the information you need to choose the ideal wood chipper for your small farm.

From considering size and power output to understanding safety precautions, this guide will help you make an informed decision. Let’s get started!

Welcome to the complete guide to wood chippers for small farms. This guide aims to provide a clear understanding of which type of wood chipper is best for your small farm, as well as some tips on how to properly maintain and use one. Even if you haven’t used a wood chipper before, this guide will get you up to speed on everything you need to know about them.

We’ll cover the various types of wood chippers that are available, their features and benefits, maintenance tips, safety considerations and more.

By the time you’ve finished reading this guide, you’ll have a thorough understanding of what kind of wood chipper is best for your small farm’s needs – from electric models all the way through industrial-grade models – as well as information on how they work and tips on proper care and usage.

Definition of wood chippers for small farms

Wood chippers refer to machines used to break down wood into smaller particles. They are specialized tools that allow small farm owners or operators to easily and quickly process wood for use in their operations. The wood chips created by wood chippers can be used as animal bedding, compost material for gardens, fuel for burning, and other applications. Depending on the intended use of the wood chips and the type of farm operation, different types of wood chippers may be necessary.

When deciding which type of wood chipper is best-suited for a small farm operation, it’s important to consider a few things: the size of the logs that need to be processed; the desired outcome (size and shape) of the chips; energy source (gasoline or electric); total power output; and cost. In addition to these considerations, a farm operator should also consider safety when using a wood chipper since they involve sharp blades or machinery that can cause injury if mishandled. Additionally, local regulations may require specific operating guidelines or certifications before workers can safely operate certain types of machines around livestock.

Importance of wood chippers for small farms

Wood chippers are an invaluable tool for small farms, as they enable farmers to quickly and efficiently reduce large volumes of material into a manageable size. Wood chippers can be used to quickly and safely clear away dead trees, brush, debris and other organic material that can cause fire hazards and provide a safe place for animals and crops. By using wood chippers for smaller farming operations, there is no need to bring in professional tree services which can be very costly.

Wood chippers come in several sizes, from light-duty “consumer” models that are perfect for home owners up through large commercial-grade machines designed for high-volume production. Depending on what the farmer’s needs are and level of available budget, wood chippers can significantly enhance the performance of any farm operation by reducing work time required for land management tasks. For instance, it takes just minutes to clear away several hundred logs with a wood chipper; this would normally take days or weeks when done manually.

In addition to simply clearing away organic material such as limbs or logs at a much faster rate than could ever be achieved manually, wood chips produced by these machines will also make up valuable fertilizing material after they have been processed further by composting or mulching. This adds yet another layer of benefits gained through owning and utilizing these powerful tools on your farm or homestead!

Brief overview of the guide

This guide offers an overview of wood chippers and their uses, with an emphasis on small farms. It is designed to provide a comprehensive understanding of the types of wood chippers available and best practices in order to ensure responsible operation.

We’ll start off by looking at the different types of wood chipping machines, their capabilities, and the kind of work they can do. Then we’ll discuss the necessary safety considerations associated with using these machines properly. Finally, we’ll look at different ways that small farms can use these machines productively and responsibly.

With this complete guide in hand, you can make informed decisions about purchasing and operating a wood chipper for your small farm needs.

Factors to Consider Before Purchasing a Wood Chipper

When considering a wood chipper for your small farm, it is important to take into account the size and type of chipping you need to accomplish. Consider the following factors in order to make an informed choice:

- Size of chipping: What are your needs? Do you need a light duty, consumer-grade machine that can efficiently handle smaller branches or do you require an industrial-grade machine for heavier use?

- Tractor compatibility: If your farm has a tractor, ensure that the wood chipper is compatible before purchasing. This will greatly reduce the time and effort required when using the chipper.

- Type of cutting blades: Single-edge blades produce higher quality chips than double-edge blades but require more frequent sharpening when processing different materials.

- Maintenance needs: Research how easy or difficult it is to maintain regular maintenance on your chosen wood chipper and what type of assurance the manufacturer provides in regard to replacing worn parts or achieving repairs if needed over time.

- Noise levels and emissions compliance: Identify whether noise levels during operation will be considered too loud by state regulations and if it complies with related emission standards.

- Space requirements/transport considerations: Keep in mind where you plan on keeping your woodchipper as well as any onsite safety measures required when transporting this equipment from one place to another at pay attention to any special requirements from local law enforcement agencies if applicable.

Size of the wood chipper

The size of the wood chipper that you select for your small farm largely depends on the size of your land and the type of trees or branches that you will be chipping. Smaller wood chippers can usually handle branches up to 3 inches in diameter, while large models may be able to chip branches up to 6 inches in diameter.

It is important to select a model that will be able to handle all of the work you need to do. If you are just cutting small trees and twigs, a smaller model will do just fine. However, if you have larger trees and heavier branches, then it is important to choose a more powerful and robust model.

Additionally, you should consider factors such as engine power, weight, noise levels, and maintenance requirements before making your final selection.

Capacity of the wood chipper

The size and capacity of a wood chipper are important considerations in selecting the right machine for your needs. Generally, wood chippers are sized according to their feed opening or diameter, which varies depending on the kind of material that is being processed: branches and small logs require smaller feed openings, while larger logs will require larger feed openings.

The capacity of the machine is typically based on the diameter of the chipping rotor and its cutting capacity, or how much material it can process per minute. A powerful motor is also important in this decision-making process so that the wood chipper can provide enough power to handle large branches or logs. Additionally, higher horsepower motors offer greater mobility when porting your wood chipper from one location to another, since heavier machines can be difficult to maneuver.

When purchasing a wood chipper it’s critical that you evaluate all these factors in combination with each other so that you can make an informed decision based on your particular needs.

Type of wood to be chipped

Before you start shopping for wood chipping equipment, it’s important to consider what type of wood will be chipped. Different types of wood require different levels of horsepower and size requirements. To ensure that you purchase the right machinery, you should consider the following factors when choosing the kind of wood to be chipped:

Softwood vs. Hardwood: Softwoods are typically easier to chip than hardwoods, since hardwoods are more dense and harder to break down into chips. Depending on your needs, softwoods such as pine or cedar may be a good choice for your operation, while oak or walnut can work well for larger chips.

Grain Structure: Wood with a straight grain structure is generally easier to chip than woods with an interlocking grain structure. If you are looking for uniform chips in a short amount of time, then hardwoods with a straight grain may be a better choice than woods with irregular grains.

Wood Age: Old and dried woods tend to break down into small pieces more easily than fresh-cut logs, although freshly cut logs can work if they are treated properly before being fed into the chipper.

Budget

When looking for the best budget wood chipper for your small farm, it is important to take into consideration the size of the machine, power it offers and the price. Consider what you will be using it for and whether you will need a self-propelled or tow-behind unit. It’s also wise to research how to safely operate a wood chipper in order to avoid injury or damage.

Lower budget wood chippers typically come with lower power ratings than more expensive models and they often lack some of the features that make operation smoother and safer. Make sure you compare different models and read reviews before choosing one so you can be sure that it is effective and safe. Additionally, always wear appropriate safety gear when operating any kind of power tool.

While budget styles may lack some extra features, they are typically still great at helping chop small branches up to 4 inches in diameter quickly and efficiently without generating too much noise or mess. Most low cost units have easier serviceability which makes them ideal for occasional use on smaller properties where easy maintenance is important. So if you are looking for an economical way of clearing away light garden waste or some small branches from your land, then a budget wood chipper may be just what you need!

Safety features

Safety features can help save you time, money, and peace of mind. When looking into purchasing a wood chipper for your small farm, it is important to consider the safety features of the machine. The following list examines some common safety features offered on wood chippers:

- Push button start: Most wood chippers are designed with a push button start feature. This eliminates the need to pull cords to start the engine and helps lessen impact on your hands and fingers.

- Emergency shut off switch: An emergency shut off switch gives you an extra layer of protection in case of any unexpected occurrences during operation, such as if something gets caught in the blade while it is running.

- Closed loop feedback system: These feedback systems monitor all actions taking place within the wood chipper, so you will be warned of possible overloading or blockages before they actually happen to reduce any potential damage or injury from occurring.

- Protective guards & screens: Many modern wood chippers come with protective guards guarding the blades from anything that may cause harm or obstruct its operations such as rocks, debris and other materials that could be thrown out during operation or land on it in transit conditions. They may also come with a protective long sleeve for added user safety when using the machine near sensitive areas like eye areas or other body parts that could be prone to injury from flying debris .

Choosing a reliable and safe wood chipper can help you make sure your small farm runs smooth and error free year round. Make sure to consider these important safety factors when choosing one for your needs!

Maintenance and Safety

Ill-maintenance of a wood chipper can cause more harm than good — from ineffective cutting to serious safety hazards. Regular maintenance helps ensure that your machine is always in its optimum operating condition, prolonging its lifespan and ensuring the safety of device and operator.

Here are some tips on how to keep your wood chiper well maintained for small farms:

- Schedule regular maintenance – Create a maintenance schedule to make sure all parts, especially blades, are operating correctly and safely. Check that all mechanical moving parts are secured properly, ensuring any dirt or debris has been cleared away. Make sure no wrong parts have been replaced during any repair by double-checking the equipment’s manual thoroughly.

- Regularly inspect the machine – Before and after use, inspect the wood chipper for damage or leaks and replace or repair any defective or malfunctioning components as soon as possible. Make sure no objects such as nails have made their way into the machine while in use; if they have, remove them meticulously before attempting to start or operate it. It is also important to check that there is enough oil present to lubricate the internal parts repeatedly during long runs, ensuring longer service life.

- Utilize protective clothing – Ensure necessary protective clothing such as gloves, earmuffs and safety glasses when dealing with your wood chipper for personal protection purposes; injury prevention must always be prioritized first when working with heavy machinery indoors or outdoors. If inclement weather such as snowfall draws near, it’s wise to check manual periodically for simple cold-weather start up techniques that will help prevent damages from occurring due to temperature changes from outdoors conditions entering inside essential machining components of the machine itself.

Importance of regular maintenance

Regular maintenance and repair of wood chippers is critical for efficient and safe operation on a small farm. Wood chippering equipment is subject to wear and tear due to vibration, debris accumulation, environmental elements and fire risk. Regular servicing can help reduce or eliminate these problems and ensure that your machine runs smoothly and safely.

In order to keep your wood chipper running properly, regular tune-ups are necessary. This includes cleaning any airways or engines of dust or debris, lubricating hinges, belts and bearings, checking for fuel leaks and inspecting blades for damage or excessive sharpening. Maintenance should also be made to the fuel lines if any signs of rust are present. Rust can weaken the lines over time and cause them to leak which could lead to a fire.

Another important maintenance factor are the safety systems that protect you from debris when operating the machine. Check for proper functioning of guards around blades as well as guards that prevent limbs from being sucked into the intake area. Regular inspections of these parts will ensure they remain safe at all times while in use. Properly maintained wood chippers will be less prone to breakdowns or malfunctions when in use on a small farm which can save time, money and potentially hazardous situations down the line.

Safety precautions when operating a wood chipper

Operating a wood chipper can be dangerous, so it’s important for small farmers to take the necessary safety precautions when using this type of equipment. Some general safety tips include:

– Wear proper clothing and protective gear such as safety glasses, hearing protection, and reflective vests.

– Make sure that your work area is free of debris as well as any obstacles such as brush or rocks.

– Make sure that all guards are in place and working properly before starting the chipper.

– Be aware of the direction which chips and debris may fly while operating the machine.

– Inform everyone within the vicinity that a wood chipper is operating in the area and exercise extra caution when children or animals are present.

– Never try to remove jammed material while the machine is running – always turn off the power first before attempting to clear a jam.

– Do not attempt to reach inside or underneath chipping mechanism with hands or tools while machine is running. Only use specially designed equipment specifically designed for removing obstructions in wood chippers when absolutely necessary and exercise caution at all times when doing so.

– Ensure operator has been properly trained in how to safely operate, maintain, troubleshoot, repair, and service their machine before using it.

Conclusion

In conclusion, many small farms can benefit from having a wood chipper available to handle the waste from timber harvesting and other forestry operations. Wood chippers are effective at shredding the biomass material safely into small pieces that can be used as mulch or added to compost. In some cases, these chips can even be used as fuel for a wood burning stove or fireplace.

It is important for small farmers to do their research before purchasing a wood chipper in order to determine what specific features and power output are necessary to meet their needs. Furthermore, it is essential to purchase a wood chipper with both safety guards and shields protections in order to avoid any potential injuries while operating the machine.

By understanding how wood chippers work, being aware of safety protocols, and researching different types of machines; small farmers will be able to find the best solution for their needs.

FAQ

What should I look for when buying a wood chipper?

You should look for the size, power, capacity, safety features, and ease of use when buying a wood chipper.

Are small wood chippers worth it?

Small wood chippers are worth it if you have a small yard or garden and need to dispose of small branches and twigs.

Is a wood chipper worth buying?

A wood chipper is worth buying if you have a large yard or garden with many trees and need to dispose of branches and twigs regularly.

Do you need training to use a wood chipper?

Yes, you need training to use a wood chipper safely and effectively.

What type of wood chipper is best?

The best type of wood chipper depends on your needs and preferences. Drum chippers are better for larger branches, while disc chippers are better for smaller branches.

How much HP does a wood chipper need?

A wood chipper needs at least 10-15 horsepower (HP) to be effective.

What size chipper do I need?

The size of the chipper you need depends on the size of the branches you want to chip. A 6-8 inch chipper is suitable for most residential needs.

What is better drum or disc on wood chipper?

Drum chippers are better for larger branches, while disc chippers are better for smaller branches.

What is the maintenance of wood chipper?

The maintenance of a wood chipper includes regular cleaning, oil changes, and blade sharpening.

What’s the difference between a chipper and a chipper shredder?

A chipper is designed to chip branches into small pieces, while a chipper shredder can also shred leaves and other yard waste.

See Also :

- Best incubator for duck eggs 2023

- Best barbed wire for cattle 2023

- Best milkhouse heater 2023

- Best cattle ear tags 2023

- Best rotary tiller for tractor 2023